January 6, 2016

Just the FAQs...Precision Measuring Indicators

Precision Measuring Indicators

Dial indicators are precision measuring tools with a myriad of applications in the science, technology and manufacturing fields. They are an essential tool in many machining and fabrication processes, but if you aren’t an engineer or a machinist, you may have wondered…

What exactly is a dial indicator?

In the simplest terms, an indicator is a distance amplifying instrument. To indicate something is to “show, or to make known,” so it makes sense that an indicator is a device that is used to precisely measure small distances and to amplify them so they can be more easily seen.

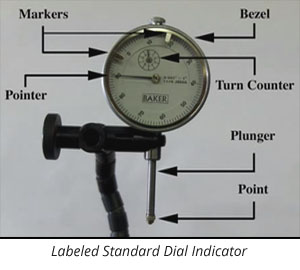

Dial indicators, so called for their dial display, are useful in situations where a small area needs to be measured and indicated. Measurements with a dial indicator are made via a plunger that moves in and out from the body of the indicator and rotates the measuring needle on the dial face. Though finer range indicators are available, dial indicators commonly have either a 1" or 2" range and are calibrated in increments of .001”. A smaller dial reads each revolution of the larger dial in increments of 0.100".

As with most things in the modern age, the dial indicator has been digitized, and there are a variety of electronic indicators available that automate the process of taking fine measurements.

What is a dial indicator used for?

Some typical situations in which indicators are useful include:

Some typical situations in which indicators are useful include:

- Checking the variation in tolerance during the inspection process of a machined part

- Measuring the deflection of a beam or ring under laboratory conditions

- Determining the accuracy of lathe or mill alignment

- Monitoring the depth of drilled holes

- Determining if edges of a rectangular workpiece are parallel

- To check the flatness of a surface before machining it

- To calibrate machinery before a production run

While commonly used in machining, fabricating and manufacturing, dial indicators are also an essential tool for precision engine building. They are necessary to measure deck clearances, crankshaft thrust and straightness, lifter travel and other precision measurements.

Is a dial test indicator the same as a dial indicator?

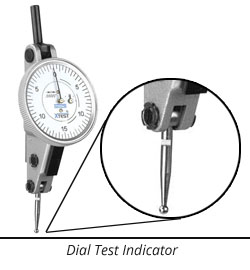

No. Where a standard dial indicator measures linear displacement, a dial test indicator measures angular displacement. It also measures much smaller differences than a standard indicator. Instead of a retracting, plunger-like probe, the test indicator utilizes a probe, or an arm, that swings in an arc from a hinge point, and measurements are taken of the degree of deflection of the arm from its resting point.

What accessories will I need for my indicator?

Contact points, or tips, of indicators are interchangeable and can come in a variety of shapes and sizes to best fit the application. This is true for both the plunger type of tip and the arm style contact point of the test indicator. Contact points can be made of steel, carbide, PVC or Teflon, and feature varying lengths and diameters. Though flat tips are available, the most common shape for the end point is spherical.

Movement of any amount will compromise indicator measurements. Therefore, indicators are almost universally mounted to a firm surface with a magnetic base via an arm. Of course, adjustable arms are the most versatile and will allow the indicator to be fitted into tight or awkward spaces that a straight arm just won’t allow. Indicators are usually mounted by utilizing the integrated stem of the indicator, or special clamps and holders can be used to attach the indicator via a dovetail on the back of the indicator body.

To ensure consistent and accurate results, store your indicators in a cabinet or special tool box. Though they may be one of your most-used measuring instruments, don’t just toss them in the toolbox with the rest of your tools.

This article was written with knowledge gained from the following articles. Feel free to visit them yourself if you’d like to read more about how indicators work.

Wikipedia - Indicators: Distance Amplifying Instrument; Mitutoyo.com: Quick Guide to Precision Instruments; Mini-lathe.com - Measurement/Dial Indicators; Hot Rod Engine ; Tech.com: How To Use a Dial Indicator; Youtube.com: How a Dial Indicator Works