Concrete Screws

Concrete screws, also known as masonry screws, anchor screws, or cement screws are specifically designed to provide quick and safe fastening for many tasks involving concrete, cement, brick, and cinder block/masonry.

Masonry screws are made of hardened steel and feature external threading, with a double lead consisting of alternating raised and lowered threads that have notches cut into them. They also feature a diamond-shaped point that resembles a nail. Using masonry screws can eliminate the need for anchors in light to medium duty applications. These screws can also be removed and re-driven into the same hole when used in concrete.

To install the screws into masonry, special carbide bits are recommended. These screws are ideal for anchoring a variety of items to masonry, such as electrical junction boxes, wooden beams, plywood, exterior insulation, metal flashing, expansion joints, duct straps, gutters, fixtures, and thresholds.

There are two head styles available: flat head and hex head. Flat head screws feature a Phillips drive, while hex head screws come in either a slotted or unslotted indented hex head.

Concrete Screw Finishes

Concrete screws typically come in three types of finishes: zinc-plated, a blue polymer finish or plain stainless steel.

Zinc-plated screws are coated with a layer of zinc to provide corrosion resistance and protection against rust. This finish is suitable for use in most indoor applications where moisture levels are low to moderate.

Stainless steel screws are made of a special type of steel that is highly resistant to rust and corrosion. This finish is ideal for use in outdoor applications or in high-moisture environments, such as swimming pools, coastal areas, and marine applications. Stainless steel screws are also very durable and can withstand exposure to harsh weather conditions and extreme temperatures.

Other types of finishes include: PermaSeal environmental coating, or with a Ruspert corrosion resistant coating. The benefits of PermaSeal and Ruspet coatings is that they are available in a variety of colors to match your application.

They are sometimes coated with a blue-colored finish for identification purposes. The blue coating serves as a visual indicator that the screws are specifically designed for use in masonry or concrete applications.

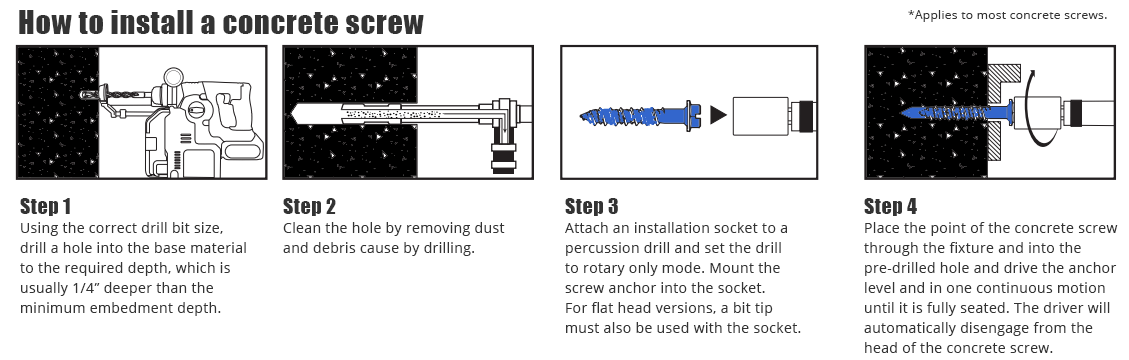

How to Screw into Concrete Using Concrete Screws

The screws should be installed a minimum of ten anchor diameters between each other, and the hole should be a depth equal to the required embedment plus ½”.

Pre-drilled holes are required before the screw can tap threads. The hole size is critical and the proper carbide drill bit should be used to ensure that the proper tolerances are met. For example, a 3/16” x 1-1/4” screw requires a 5/32” x 3-1/2” drill bit.

Brands Comparable to Tapcon® Screws

Masonry screws are commonly called Tapcons, which are actually just a brand of concrete screws. Throughout the years, the two name have been used interchangeably.

AFT offers a wide selection of masonry screw brands including: Power-Con, Strongpoint Strongcon, Dewalt Ultracon, Dewalt Aggre Gator, Dewalt Crete Flex, US Anchor TapKing, Daggerz Quick-Con, and Daggerz Dagger-Con.