What is Copper Plating?

Copper plating process provides excellent electrical conductivity, only exceeded by silver plating, and good corrosion resistance when used as an undercoat for other plated coatings. Copper finishes range from matte to very shiny, and there are several copper plating processes available at AFT. Each process is designed for a specific purpose, ranging from decorative to heat treat stop-off.

Cyanide based bath chemistry produces a matte finish, which is favored for its diffusion blocking character. It is also necessary for plating on aluminum, steel and zinc, as it adheres well and minimizes immersion deposits. Cyanide copper has excellent throwing power, which leads to less variations in thickness.

AFT has extensive experience in plating stainless steel threaded parts for the petroleum industry to reduce galling of stainless valves and parts.

What are the benefits of Copper Plating?

- Anti-galling on stainless steel threaded oil industry parts

- Good solderabiltiy

- Underplating to enhance adhesion of deposits of other metals

- Copper plated bolts, nuts and screws possess improved electrical properties.

- Impairs migration of alloying elements

- Copper plated parts boast improved overall corrosion resistance

- Soft and ductile for decorative finishes

AFT's Copper Plating Chemistry and Production:

Mil - C - 14550B

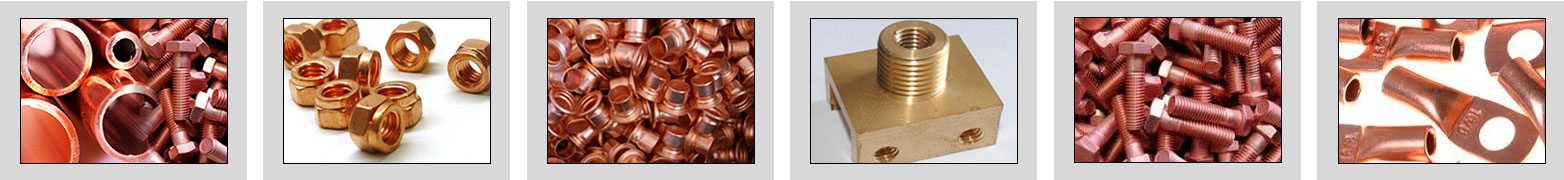

Copper Screws - Copper Bolts and Nuts

AFT Fasteners can provide a quote for custom plated copper screws, copper bolts and nuts or any other copper plated fasteners. Copper plating is a cost-effective alternative to silver plating as it provides excellent electrical conductivity.

VAM Certified Services:

AFT is a VAM Certified Applicator

AFT is a VAM Certified Applicator

AFT possesses a process of immersion copper plating which has been qualified as per the VAM Specifications, and is qualified to apply its immersion copper plating process on VAM Connections.

Assurance has been obtained at AFT process controls, quality control procedures and training organization are compliant with the requirements imposed by VAM Services.

Purchase from AFT or Supply Your Own Parts

When having parts plated, coated, or painted at our metal finishing facility, AFT offers customers the option to either supply their own parts or purchase them directly through AFT. In most circumstances, buying the parts directly from AFT can be significantly less expensive due to lower shipping costs and our competitive pricing.

We offer low minimums, and turn-around times are typically within 7 days. Please contact us with any questions or to request a quote.