| Countersunk Finishing Washers | ||||||

|---|---|---|---|---|---|---|

|

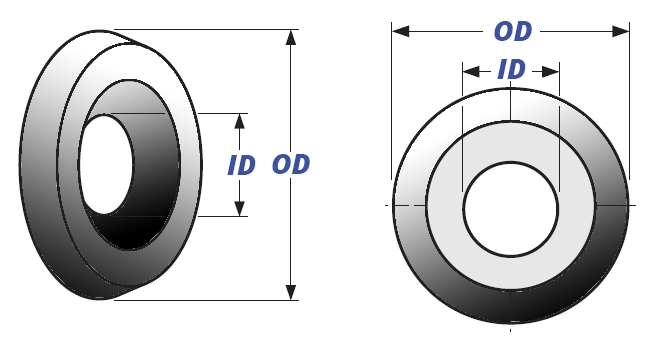

Screw Size |

Outside Diameter (OD) |

Inside Diameter (ID) |

Overall Height |

|||

| Max | Min | Max | Min | Max | Min | |

| #4 | .375 | .334 | .150 | .113 | .103 | .078 |

| #6 | .469 | .424 | .200 | .161 | .103 | .078 |

| #8 | .543 | .518 | .220 | .180 | .110 | .086 |

| #10 | .606 | .581 | .279 | .235 | .126 | .103 |

| #12 | .704 | .656 | .299 | .259 | .138 | .113 |

| 1/4 | .794 | .762 | .338 | .305 | .156 | .125 |

| 5/16 | .938 | .864 | .409 | .373 | .188 | .141 |

| 3/8 | 1.125 | .980 | .460 | .425 | .260 | .235 |

NOTE: Currently, there is no single set of requirements accepted as the industry standard for countersunk finishing washers.

As a guideline for what's accessible, we give these sizes. If it is critical to meet particular dimensions, verify with your provider.

|

|

|

||||||||||||||

Applications/ Advantages |

|

||||||||||||||

|

|

Steel: Washers are to be punched from hot-rolled, hot-rolled and pickled, cold-rolled steel, machined from bar stock or tubing, or forged at the option of the manufacturer. |

||||||||||||||

| Plating |

Typically, finishing washers are plated with nickel, black oxide as well as other coatings. Generally, |

||||||||||||||