| Drive Screws - Round Head Type U (ASME B18.6.3-2013) | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

|

Nominal |

Number of Thread Starts | Outside Diameter (D) |

Head Diameter (A) |

Head Height (H) |

Pilot Diameter (P) |

Recommended Hole Size |

||||||

| Max | Min | Max | Min | Max | Min | Max | Min | Drill Size No. |

Hole Diameter | |||

| 00 | 6 | .060 | .057 | .099 | .090 | .034 | .026 | .049 | .046 | 55 | .052 | |

| 0 | 6 | .075 | .072 | .127 | .118 | .049 | .041 | .063 | .060 | 51 | .067 | |

| 2 | 8 | .100 | .097 | .162 | .146 | .069 | .059 | .083 | .080 | 44 | .086 | |

| 3 | 8 | .108 | .104 | .187 | .169 | .078 | .067 | .090 | .086 | 41 | .096 | |

| 4 | 7 | .116 | .112 | .211 | .193 | .086 | .075 | .096 | .092 | 37 | .104 | |

| 5 | 7 | .128 | .124 | .236 | .217 | .095 | .083 | .106 | .102 | 35 | .110 | |

| 6 | 7 | .140 | .136 | .260 | .240 | .103 | .091 | .116 | .112 | 31 | .120 | |

| 7 | 8 | .154 | .150 | .285 | .264 | .111 | .099 | .126 | .122 | 29 | .136 | |

| 8 | 8 | .167 | .162 | .309 | .287 | .120 | .107 | .136 | .132 | 27 | .144 | |

| 10 | 8 | .182 | .177 | .359 | .334 | .137 | .123 | .150 | .146 | 20 | .161 | |

| 12 | 8 | .212 | .206 | .408 | .382 | .153 | .139 | .177 | .173 | 11 | .191 | |

| 14 | 9 | .242 | .236 | .457 | .429 | .170 | .155 | .202 | .198 | 2 | .221 | |

| 5/16 | 11 | .315 | .309 | .590 | .557 | .216 | .198 | .272 | .267 | M | .295 | |

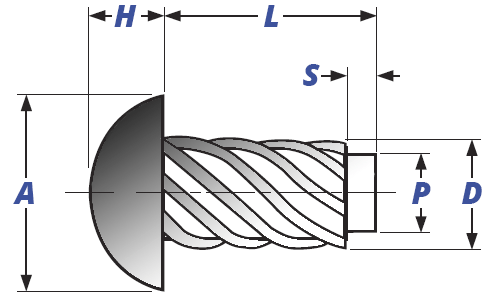

| L | Nominal Screw Length | 1/8 | 3/16 | 1/4 | 5/16 | 3/8 | 1/2 | 5/8 | 3/4 | 1" and Over | ||

| Tolerance on Length | ±0.02 | ±0.02 | ±0.02 | ±0.02 | ±0.02 | ±0.03 | ±0.03 | ±0.03 | ±0.03 | |||

| S | Pilot Length (±0.015) | .047 | .047 | .047 | .047 | .062 | .062 | .078 | .078 | .125 | ||

NOTE: Sizes for #3 & #5 Drive screws are independent of the ASME B18.6.3 standard.

316 Stainless Steel

| Description |

Round metal drive screw with various large helix angle start threads with a pivot. |

||

| Applications/Advantages | When compelled into the job under pressure to make continuous fastenings in metals and plastics. | ||

| Material |

Steel |

Stainless | |

|

AISI 1016 - 1024 or equivalent steel |

18-8 Stainless Steel |

316 Stainless Steel |

|

| Heat Treatment |

Screws should be quenched in liquid first and then tempered by reheating to 650°F minimum. |

- |

- |

| Case Hardness |

Rockwell C 45 minimum |

Rockwell B 85 - 95 (approximate)

|

Hardness: Rockwell B 85 - 95 (approximate) |

| Core Hardness |

Rockwell C 28-38 |

||

| Case Depth |

No.2 through 6 diameter: .002-.007 No.7 through 12 diameter: .004-.009 |

- |

- |

| For Use In |

Drive screws, when pushed into correctly sized holes in test plates with a Rockwell hardness of B70 to B85, generate mating threads without thread shaving or screw fracture. |

Not recommended use in materials of a hardness greater than Rockwell B65. |

Not recommended to use in materials of a hardness greater than Rockwell B65. |

| Plating |

See table above for more info. |

Typically parts are delivered without secondary finishes. |

|