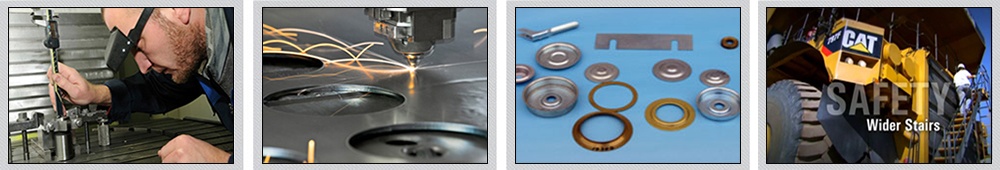

As a full service sheet metal fabricator and metal parts manufacturer, AFT Manufacturing excels at meeting the stringent policies of this industry. We are known for precision engineering, producing quality products, on-time delivery and competitive pricing. At AFT, we think of each customer as a partner, and we work hand in hand with our partners as each project flows from concept to completion. This communication ensures that each project meets or exceeds our customers' expectations.

AFT Manufacturing…

- Can perform short run, medium run and progressive die stampings.

- Specializes in superior quality metal parts fabrication.

- Works with numerous production materials including: steel, stainless steel, aluminum and yellow metals.

- Offers complete in-house design, engineering and tool room support.

- Has internationally acclaimed process design and assembly lines.

- Can complete value-added assembly services. Sub-assembly and/or Final-assembly

- Offers prototyping and engineering services.

Design Engineering Consultants

Every project begins with a customer's plan or one of our own professionally engineered designs. Putting our decades of experience in CAD and the metal stamping and fabrication business to work, we partner with you to form a plan for all customer logistics from pre-project scope development to final delivery. We strive to make sure that we meet or exceed design specifications. Whether you are developing a prototype or ready for full scale production of parts, tools or dies, our design engineering consultants are here to make your project a success.

AFT also specializes in various types of tool and die creation, maintenance and repair. This enables us to devise the most economic tooling to fit the production needs of our customers, ranging from prototypes to large quantity runs with minimal lead time.

Laser Cutting

Sheet metal laser cutting is one of the most sought after processes in metal fabrication, possessing several benefits over mechanical cutting such as increased precision with less warping and contamination. Using the most trusted name in laser cutting technology, the Trumpf TruLaser 3030, AFT is equipped to handle your company's laser cutting requirements.

Sheet Metal Fabrication

Upon completion of the planning and design phase, AFT puts its expertise in sheet metal fabrication and forming to work to produce high-quality sheet metal parts in the quickest turn-around time possible. Low-tolerance precision parts require precision fabrication, which AFT excels at.

AFT Manufacturing specializes in:

- Laser and Traditional Cutting, including sawing, shearing, chiseling and CNC

- Welding Fabrication which encompasses welding, joining with adhesives, fasteners and rivets

- Bending via manual or powered hammering using press brakes and machinery

Sheet Metal Fabrication

Some metal fabrications that AFT produces are used by such heavy duty machines as the Caterpillar 797, where parts must be fabricated to endure extreme conditions while providing reliable endurance and safety to people and equipment. Providing top-notch sheet metal fabrications with excellent customer service is our highest priority. Call or contact us today to discuss how AFT can help you.

Metal Stamping

With our high-capacity, multi-ton presses and metal forming equipment, AFT is ready for any project. Our 30,000 square foot plant allows us to maintain a substantial on-site metal inventory in order to meet tight customer schedule requirements, while also giving us space to handle projects of varying scope. No matter how complex your precision metal stamping project, AFT Manufacturing is equipped to tackle it.

|

Materials:

|

Stamping Processes:

|

Metal Assembly Services

Component assembly - joining two or more parts into a final assembled product -- is just one of the value-added services that AFT provides. We assess your product's specifications, assemble, and deliver a quality-assured product. Our customers save time and resources by outsourcing their component assembly to AFT.

Quality Assurance

As an ISO certified manufacturing company, AFT practices rigorous quality control. We are only successful when our customer's expectations are met in full. Our philosophy is that "Quality Control is EVERY person's responsibility on EVERY project." We perform precision tests at various points in a project's life cycle to assure that our customers are satisfied with the final product delivered.

Don’t just take our word for it. Here are some of the kind words our customers have to say about us:

"AFT Manufacturing produces top quality and reliable parts for our heavy duty machinery. As with all Caterpillar products, parts must meet the highest quality and standards. AFT Manufacturing is a consistent contributor to our manufacturing processes."

- Caterpillar Trucks & Tractors

"AFT had to meet an extremely tight deadline for us. Not only did they come through on time; the finished part was of the highest quality."

"They saved my company both time and money with their outstanding pre-production ideas. They've got my next order."

- Myers Industries Purchasing Manager

"AFT took my product from start to finish which included design, engineering, fabrication, assembly and shipping. They are a well-organized and managed company."

- Big "M" Manufacturing (HVAC Equipment Manufacturers)

"Our jobs have been small, but the people at AFT offered us competitive pricing and treated us like we are one of their biggest customers."

- Reel Manufacturing Company

Please contact us to request a quote or call 877-844-8595, to find out how AFT Manufacturing can put our knowledge of the metal fabrication business to work for you.