| 2A External Threads For Machine Screws And SEMS (ASME B 1.1 (2008)) | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

|

Nominal Size & Threads per Inch |

Series Designation |

Allowance |

Major Diameter | Pitch Diameter | Stress Area, in2 |

Tensile Strength, a lb., min. (STEEL screws only) |

||||

| Max | Min | Max | Min | Tolerance | ||||||

| 0-80 0.060 | UNF | .0005 | .0595 | .0563 | .0514 | .0496 | .001762 | 0.00180 | - | |

| 1-64 0.073 | UNC | .0006 | .0724 | .0686 | .0623 | .0603 | .001970 | 0.00263 | - | |

| 1-72 0.073 | UNF | .0006 | .0724 | .0689 | .0634 | .0615 | .001899 | 0.00278 | - | |

| 2-56 0.086 | UNC | .0006 | .0854 | .0813 | .0738 | .0717 | .002127 | 0.00370 | - | |

| 2-64 0.086 | UNF | .0006 | .0854 | .0816 | .0753 | .0733 | .002040 | 0.00394 | - | |

| 3-48 0.099 | UNC | .0007 | .0983 |

.0938 |

.0848 | .0825 | .002302 | 0.00487 | - | |

| 3-56 0.099 | UNF | .0007 | .0983 | .0942 | .0867 | .0845 | .002191 | 0.00523 | - | |

| 4-40 0.112 | UNC | .0008 | .1112 | .1061 | .0950 | .0925 | .002507 | 0.00604 | 360 | |

| 4-48 0.112 | UNF | .0007 | .1113 | .1068 | .0978 | .0954 | .002361 | 0.00661 | 396 | |

| 5-40 0.125 | UNC | .0008 | .1242 | .1191 | .1080 | .1054 | .002562 | 0.00796 | 470 | |

| 5-44 0.125 | UNF | .0007 | .1243 | .1195 | .1095 | .1070 | .002484 | 0.00830 | 498 | |

| 6-32 0.138 | UNC | .0008 | .1372 | .1312 | .1169 | .1141 | .002820 | 0.00909 | 550 | |

| 6-40 0.138 | UNF | .0008 | .1372 | .1321 | .1210 | .1184 | .002614 | 0.01015 | 609 | |

| 8-32 0.164 | UNC | .0009 | .1631 | .1571 | .1428 | .1399 | .002916 | 0.0140 | 850 | |

| 8-36 0.164 | UNF | .0008 | .1632 | .1577 | .1452 | .1424 | .002804 | 0.01474 | 884 | |

| 10-24 0.190 | UNC | .0010 | .1890 | .1818 | .1619 | .1586 | .003319 | 0.0175 | 1050 | |

| 10-32 0.190 | UNF | .0009 | .1891 | .1831 | .1688 | .1658 | .003004 | 0.0200 | 1200 | |

| 12-24 0.216 | UNC | .0010 | .2150 | .2078 | .1879 | .1845 | .003400 | 0.0242 | 1450 | |

| 12-28 0.216 | UNF | .0010 | .2150 | .2085 | .1918 | .1886 | .003224 | 0.0258 | 1548 | |

| 1/4-20 0.250 | UNC | .0011 | .2489 | .2408 | .2164 | .2127 | .003731 | 0.0318 | 1900 | |

| 1/4-28 0.250 | UNF | .0010 | .2490 | .2425 | .2258 | .2225 | .003322 | 0.0364 | 2200 | |

| 5/16-18 0.3125 | UNC | .0012 | .3113 | .3026 | .2752 | .2712 | .004041 | 0.0524 | 3150 | |

| 5/16-24 0.3125 | UNF | .0011 | .3114 | .3042 | .2843 | .2806 | .003660 | 0.0580 | 3480 | |

| 3/8-16 0.375 | UNC | .0013 | .3737 | .3643 | .3331 | .3287 | .004363 | 0.0775 | 4650 | |

| 3/8-24 0.375 | UNF | .0011 | .3739 | .3667 | .3468 | .3430 | .003804 | 0.0878 | 5268 | |

| 1/2-13 0.500 | UNC | .0015 | .4985 | .4876 | .4485 | .4435 | .004965 | 0.1419 | 8500 | |

| 1/2-20 0.500 | UNF | .0013 | .4987 | .4906 | .4662 | .4619 | .004288 | 0.1599 | 9594 | |

| Tolerance on Length | Nominal Screw Size | Nominal Screw Length | ||||||||

| Up to 1/2 in., incl. | Over 1/2 to 1 in., incl. | Over 1 to 2 in., incl. | Over 2 in. | |||||||

| 0 thru 12 | -0.02 | -0.03 | -0.06 | -0.09 | ||||||

| 1/4 thru 3/4 | -0.03 | -0.03 | -0.06 | -0.09 | ||||||

*Tensile strength values are supported 60,000 psi and apply to carbon steel screws and SEMS solely. Hex and Hex Washer Head Machine Screws of enough length is also wedge tensile tested. Different head designs is also axial tensile tested.

| Mechanical & Performance Requirements | ||||||

|---|---|---|---|---|---|---|

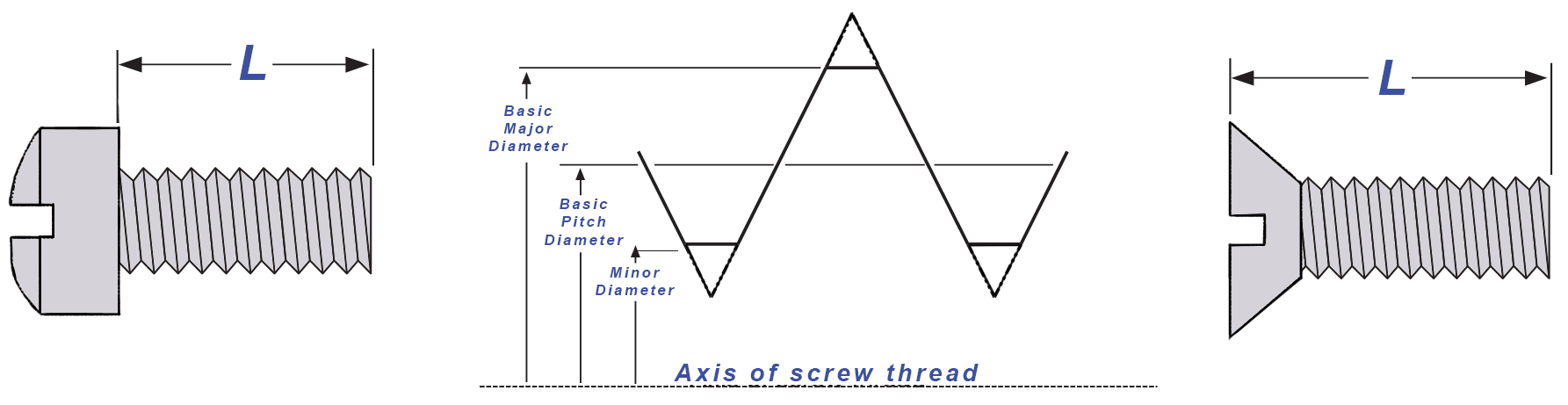

| Description | A straight shank fastener with external threads designed to travel through a hole or nut that's pre-tapped to make a mating thread for the screw. | |||||

|

Applications/ |

Steel | Stainless | Aluminum | |||

|

The most common and most famous variety of steel machine screws is Steel Zinc. |

In food processing machinery and cooling devices, 18-8 Stainless Steel machine screws are used in applications requiring general atmospheric corrosion resistance. In resisting any elevation in application operating temperature when retaining its strength, stainless is also superior to steel. 316 Stainless Steel has superior 18-8 corrosion resistance and is superior at elevated temperatures to preserve its strength. |

Aluminum machine screws can be a less costly alternative to stainless screws in some applications because of their corrosion resistance and high conductivity rate. To reduce the risk of galvanic corrosion, aluminum machine screws should be fastened with aluminum nuts. | ||||

| Material | AISI 1006 - 1022 or equivalent steel. | SAE 18-8 stainless steel |

316 stainless steel |

410 stainless steel | 2024-T4 alloy | |

| Hardness |

Rockwell B70 - B100. |

Rockwell B85 - B95 (approximate)* | Rockwell B85 - B95 (approximate)* | Rockwell C34 (approximate) | - | |

|

Tensile Strength |

|

80,000 psi. minimum (100,000 psi after cold working)* |

|

|

|

|

| Steel machine screws that are smaller than #4 in nominal diameter are not subject to tensile inspection. Machine screws No. 4 and No. 5 that are shorter than 1/2” are not subject to tensile testing. Tensile testing is not conducted on steel machine screws of diameter 6 to 1/2" inclusive, which are shorter than either 1/2" or 3D (where D is the nominal screw size in inches).

Such steel machine screws of the size to be measured must comply with the specifications for tensile loads set out above. |

||||||

|

Plating |

- | Stainless machine screws are typically delivered plain or finished in black oxide. | Normally, Aluminum machine screws are supplied without any extra finish. | |||

*Only for stainless machine screws, hardness and tensile strength requirements are provided as guides. For stainless machine screws, there is currently no national standard for these performance specifications.