| A325 High Strength Tension Control Bolts: Dimensions | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

|

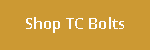

Nominal Bolt Size Click on the size to shop products |

Body Diameter (E) | Diameter of Bearing Surface (D) | Height (H) | Radius of Fillet (R) | Thread Length (LT) | Transition Thread Length (Y) | |||||

| Max | Min | Max | Min | Basic | Max | Min | Max | Min | Basic | Max Ref | |

| 5/8 | .642 | .605 | 1.181 | 1.102 | 25/64 | .403 | .378 | .062 | .021 | 1.25 | .22 |

| 3/4 | .768 | .729 | 1.417 | 1.338 | 15/32 | .483 | .455 | .062 | .021 | 1.38 | .25 |

| 7/8 | .895 | .852 | 1.654 | 1.535 | 35/64 | .563 | .531 | .062 | .031 | 1.50 | .28 |

| 1 | 1.022 | .976 | 1.900 | 1.771 | 39/64 | .627 | .591 | .093 | .062 | 1.75 | .31 |

| Heavy Hex Nuts Used with Tension Control Bolts | ||||||||

|---|---|---|---|---|---|---|---|---|

|

Nominal Nut Size |

Width Across Flats (F) |

Width Across Corners (G) | Height (H) | |||||

| Basic | Max | Min | Max | Min | Basic | Max | Min | |

| 5/8 | 1-1/16 | 1.062 | 1.031 | 1.227 | 1.175 | 39/64 | .631 | .587 |

| 3/4 | 1-1/41 | 1.250 | 1.212 | 1.443 | 1.382 | 47/64 | .758 | .710 |

| 7/8 | 1-7/16 | 1.438 | 1.394 | 1.660 | 1.589 | 55/64 | .885 | .833 |

| 1 | 1-5/8 | 1.625 | 1.575 | 1.876 | 1.796 | 63/64 | 1.012 | .956 |

| Washers Used with Tension Control Bolts | ||||||

|---|---|---|---|---|---|---|

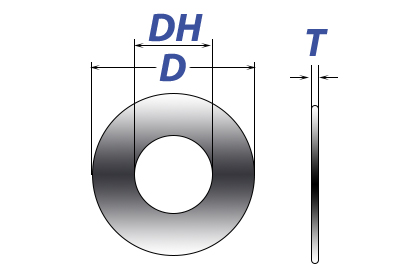

|

Nominal Nut Size |

Outside Diameter (D) |

Hole Diameter (DH) | Thickness (T) | |||

| Nom. | Tolerances | Nom | Tolerances | Max | Min | |

| 5/8 | 1-5/16 | -1/32, +1/4 | 11/16 | -0, +1/32 | .177 | .122 |

| 3/4 | 1-15/32 | -1/32, +1/4 | 13/16 | -0, +1/32 | .177 | .122 |

| 7/8 | 1-3/4 | -1/32, +1/4 | 15/16 | -0, +1/32 | .177 | .136 |

| 1 | 2 | -1/32, +1/4 | 1-1/8 | -0, +1/32 | .177 | .136 |

| Tension Control Bolts: Performance & Mechanical Stats | ||||

|---|---|---|---|---|

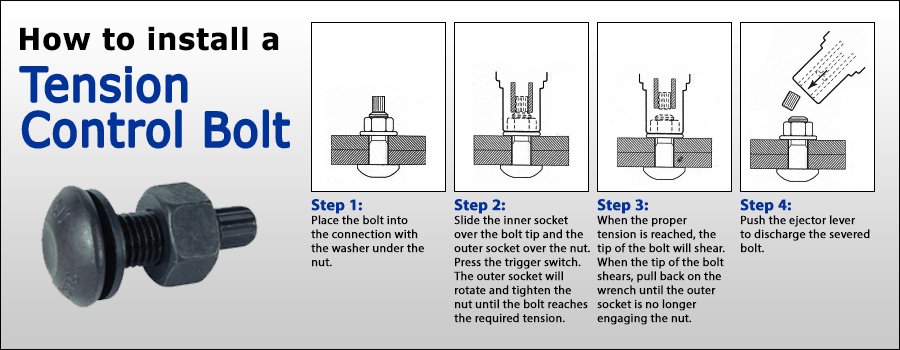

| Description | A three piece fastening system consisting of: 1) a round-head bolt with a truncated, flat surface area at the top of the bolt, and a 24-sided tip which protrudes from the opposite end. The tip is calibrated to shear off when the proper tension is achieved; 2) a 2H heavy hex nut; and 3) a structural flat washer. | |||

| Applications | Commonly used in structural steel joints in heavy construction. Has several advantages over traditional structural bolts, including: A) No operator or tool can over torque the fastening, B) the fastening can be visually inspected - when the tip is gone, the tension is correct, C) installation is fast, easier and done by one person, D) installation process is quieter. | |||

| Bolt | Nut | Washer | ||

| Material |

Type 1 bolts shall be made from a carbon steel, which conforms to the following chemical composition requirements: Carbon: 0.25-0.58%, Manganese: 0.60% min, Phosphorus: 0.048% max; Sulfur: 0.058% max | 2H nuts shall be made from a carbon steel, which conforms to the following chemical composition requirements: Carbon: 0.40% min, Manganese: 1.00% max, Phosphorus: 0.040% max, Sulfur: 0.050% max, Silicon: 0.040% max | Type 1 washers shall be made from a steel, which conforms to the following chemical composition requirements: Phosphorus: 0.050% max, Sulfur: 0.060% max | |

| Heat Treatment | Type 1 bolts shall be heat treated by quenching in a liquid medium from above the austenitizing temperature and then tempered by reheating to a temperature at least 800 Degrees (F). | 2H nuts shall be heat treated to meet the required mechanical properties. | Washers shall be through hardened. | |

| Hardness |

5/8" - 1" D: Rockwell C24-35 |

Rockwell C24-38 | Rockwell C38-45 | |

| Proof Load |

5/8" - 1" D: 85,000 psi |

175,000 psi |

|

|

| Yield Strength |

5/8" - 1" D: 92,000 psi |

|||

| Tensile Strength |

5/8" - 1" D: 120,000 psi min |

|||